Custom Metal Stamping Manufacturer in China

Precision Metal Stamping | Deep Drawing | Custom Hardware | Tolerance ±0.1mm | One-Stop Service from Tooling to Mass Production

Why Choose PengCe Metal?

We are not just a supplier, we are your technical partner

Production Stability & Durability

Strict production according to customer drawings ensures batch consistency. Product quality and durability stand the test of time, winning consistent customer praise.

Batch Consistency GuaranteedEngineering Excellence

Capable of manufacturing complex shapes that other factories cannot achieve. Our technical team leverages rich experience to help solve design challenges and optimize assembly.

Solving Complex ChallengesFast Delivery, Zero Returns

Multi-stage integrated stamping significantly reduces production cycles. From tooling to shipping, every step is rigorously controlled for perfect fit and extremely low rejection rates.

Full-Process Quality ControlHow We Solved a Critical Tolerance Challenge

This is what sets PengCe apart from ordinary contract manufacturers - we understand technology, we can rescue your project

From ±0.5mm to ±0.1mm Precision Leap

The Challenge

- • Previous supplier could not solve dimension deviation issues

- • Deviation as high as ±0.5mm

- • 40% rejection rate during injection/assembly

- • Over a dozen failed trials, facing deadline crisis with major brand

Our Solution

- • Engineering team analyzed and disassembled the original mold

- • Identified missing Stop Plate in mold structure

- • Redesigned mold with Stop Plate to precisely control material flow

The Results

Precision Tolerance Achieved

Reduced from ±0.5mm to ±0.1mm

Assembly Rejection Rate

Dropped from 40% to 0%

Long-term Partnership

Client signed long-term agreement and transferred other orders

Diverse Manufacturing Capabilities

Precision components for industrial, commercial, and consumer applications

Progressive Die Stamping

This is a highly efficient and precise mass production process. Through a single integrated mold and automated feeding system, metal coils/strips undergo multiple processing steps in a single feed, including punching, bending, stretching, flanging, and stamping, ultimately producing finished or semi-finished products. All processes are completed on the same mold, ensuring a unified positioning reference for parts and avoiding positioning errors caused by multiple process transfers. Dimensional tolerances can be controlled to ±0.05mm or even higher precision, resulting in extremely high consistency. It is particularly suitable for the mass production of standardized small hardware accessories, such as electronic connector terminals, appliance clips, automotive stamping parts, and metal springs.

45T - 600T CapacityDeep Drawing

Deep drawing is a cold forming process mainly used to stamp thin metal sheets (such as steel, aluminum, and stainless steel sheets) using molds to process them into hollow, complex-shaped hardware parts with a depth greater than their diameter/width in one step or in stages. It boasts significant advantages such as high efficiency, high precision, and low cost, and also offers high material utilization, saving costs. The key to deep drawing lies in controlling the uniformity of metal flow to avoid defects such as cracking, wrinkling, and uneven wall thickness. It is widely used in the production of hardware parts in industries such as automotive, home appliances, construction, and aerospace.

Depth up to 150mmThinning And Stretching

This is a special deep drawing technique where the workpiece's wall thickness actively decreases during the drawing process, while the inner and outer diameters expand simultaneously, resulting in hollow hardware parts with thin walls, thick bases, and high height. It differs from ordinary drawing (which aims to increase height without intentionally reducing wall thickness). Through multiple drawing operations, the part's wall thickness is uniformly thinned, producing high-precision thin-walled parts. It is widely used in precision hardware components, such as electronic connector housings, automotive fuel injector sleeves, and metal cartridge parts.

Tolerance ±0.05mmSecondary Operations

Common secondary processing techniques for hardware accessories are mainly divided into four categories: precision processing (cutting, CNC machining, polishing and grinding), surface treatment (electroplating, oxidation, spraying and powder coating, passivation and phosphating), functional enhancement processing (heat treatment, roll forming), and auxiliary secondary processing (deburring, tapping and threading).

In-house ProcessingFeatured Products

Precision in every detail - samples of our manufacturing excellence

Deep Drawn Aluminum Cup

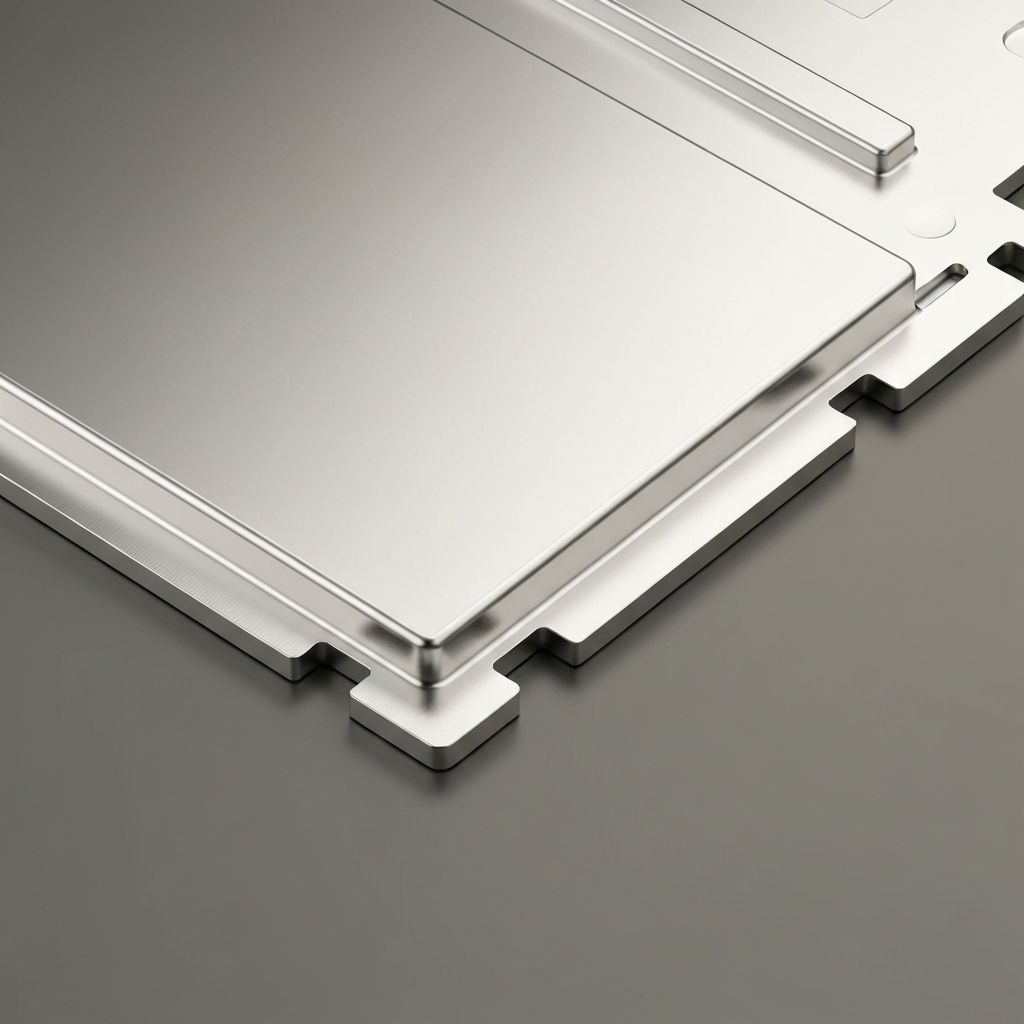

EMI Shielding Cover

Switch Contacts

Electrical Terminals

Don't see your part type? We can custom manufacture according to your drawings.

Upload Drawing for Custom QuoteWide Range of Materials & Finishes

Supporting all mainstream materials and comprehensive surface treatment options

Materials

Surface Finishes

What Our Clients Say

"PengCe solved our long-standing aluminum cup tolerance issues, reducing from ±0.5mm to ±0.1mm. Assembly rejection rate dropped from 40% to 0%. Their technical capability is truly impressive!"

Zhang Wei

Purchasing Manager - Lighting Company

"Very fast response, solved tolerance problems we had with other suppliers. Consistent quality, on-time delivery. We have been partners for 3 years now."

Mark S.

Engineering Director - US Electronics Co.

"As long-term partners for L-brackets, their quality consistency is excellent. Fine detail work, easy installation, solved our backend assembly fitting issues."

Li Jun

Supply Chain Manager - Furniture Hardware

Virtual Factory Tour & Quality Control

Explore our advanced production facilities and comprehensive quality inspection equipment

ISO Quality Management Certified

Strict full-process quality control according to ISO standards

In-house Tooling Workshop

Own tool room for fast delivery and reduced tooling costs

Advanced Inspection Equipment

Projector, tensile tester, salt spray chamber and more

Export Standard Packaging

VCI rust-prevention bags, custom blister trays, wooden cases

Xiamen Port Advantage

Support FOB/CIF/DDP shipping terms, global fast delivery

Trusted Across Industries

Lighting & LED

Electronics

Furniture

Automotive

Industrial

Request a Quote

Quick response, global fast delivery

David Chen

Sales Engineer

15+ years in precision stamping. I will personally review your project and provide professional DFM suggestions.

What You Get

- Response within 24 hours

- Free DFM analysis report

- Detailed cost breakdown

- Sample available